More than 60 years working in the development of technologies and solutions for corrosion protection.

THE COMPANY

TRADITION AND INNOVATION

Since 1961, Tinôco Anticorrosão has been developing technologies and solutions for corrosion protection in areas and equipment considered critical to the industry.

We have developed an elastomeric, environmentally friendly, and cold applied coating technology that offers excellent barrier protection which has excellent and proven performance in various industrial sectors in different environmental conditions.

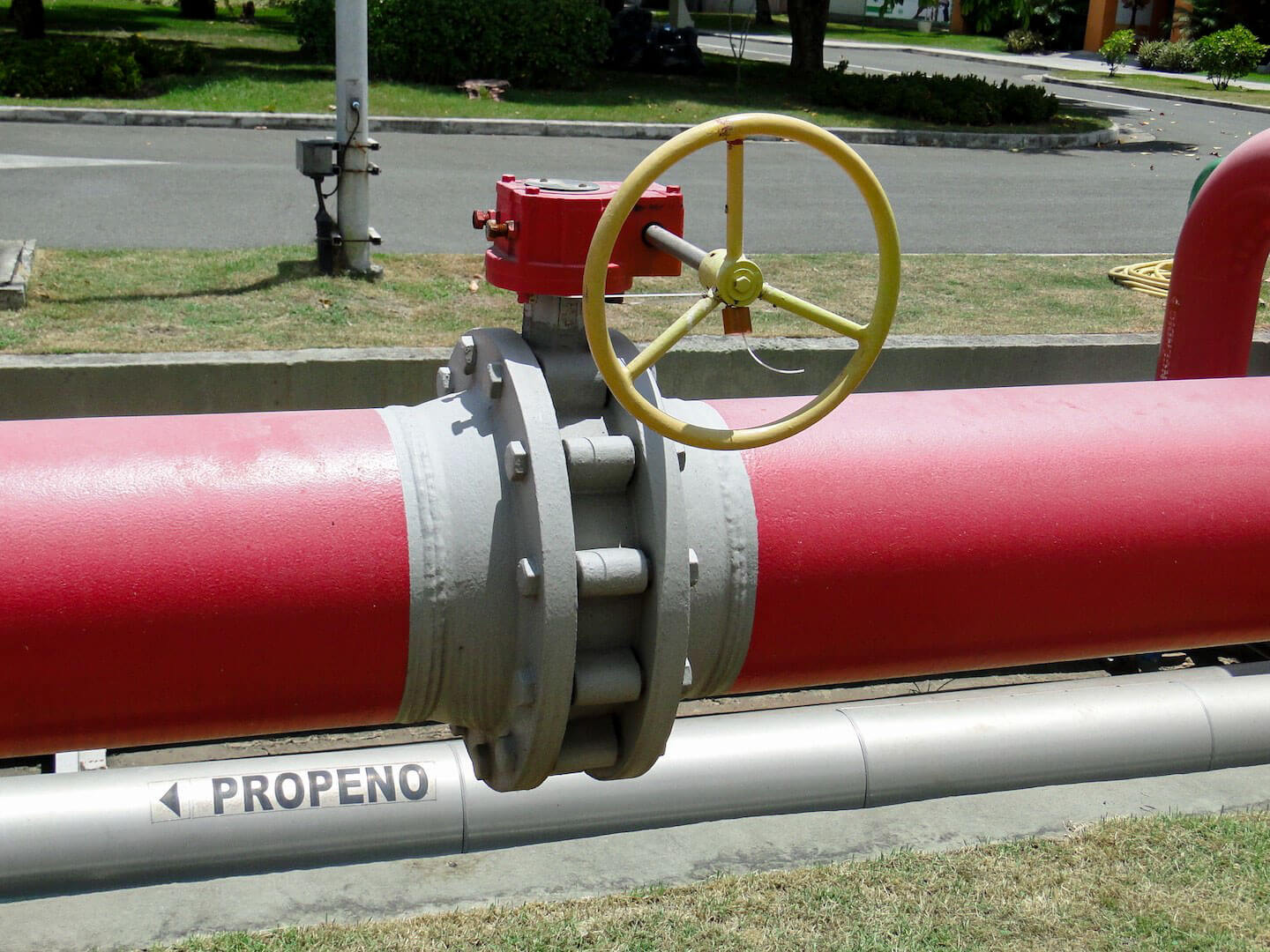

The Securit™ 2 Elastomer system has revolutionized corrosion protection methods, achieving exceptional results in flanges, valves, screws, junction splints, steel and concrete interfaces, pipes support, and other structures of complex geometry and in critical areas

SECURIT™ 2 ELASTOMER IT IS 100% BRAZILIAN TECNOLOGY

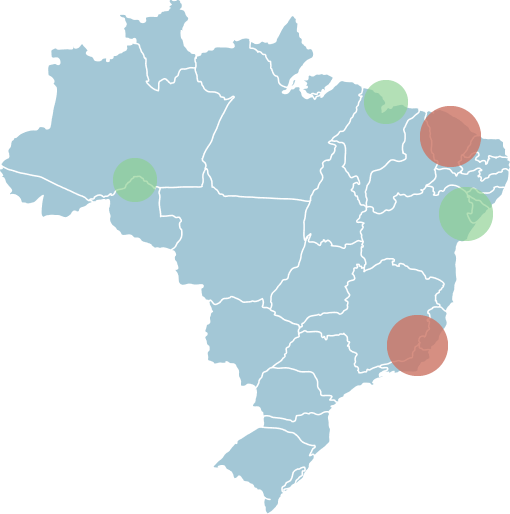

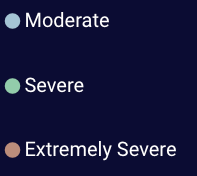

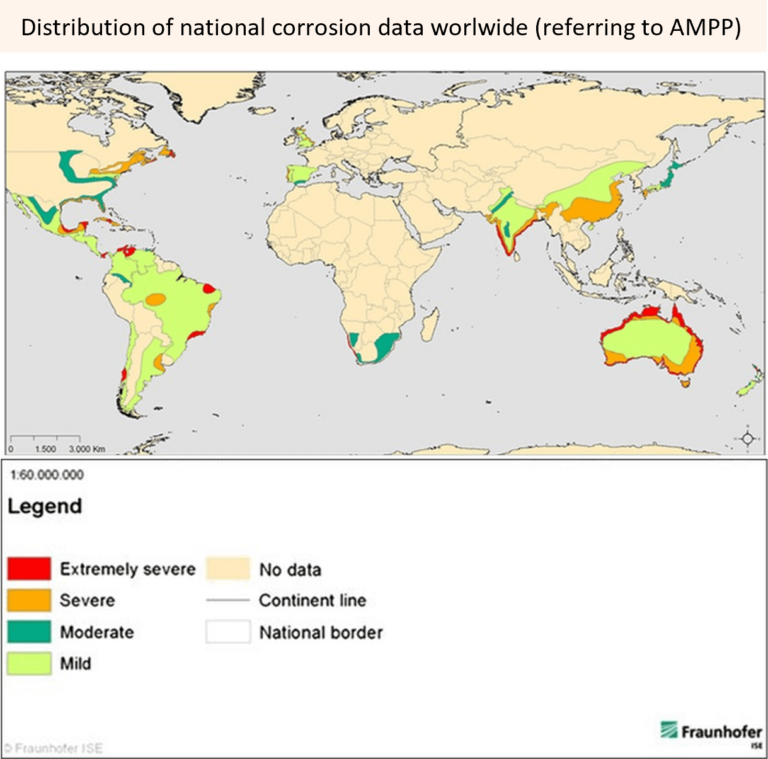

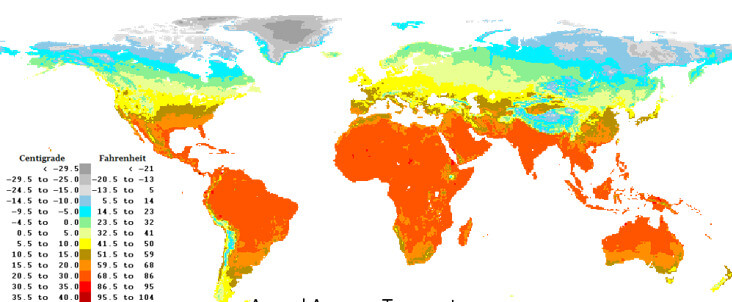

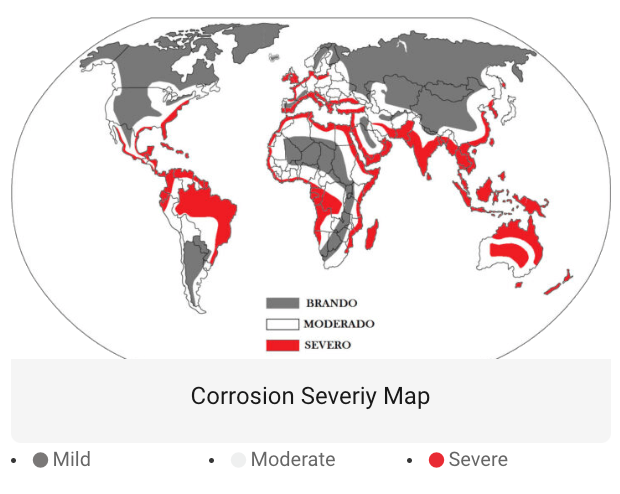

We emphasize that, at present our activities are in Brazil, a country of continental extension that has most of its territory located within the Earth’s Tropical Zone, an area with a high incidence of heat and ultraviolet radiation. The northern region of the country is cut off by the equator and the entire coastal region to the east is bathed by the Atlantic Ocean. Geographical factors and climatic conditions such as atmosphere temperature, sea air and the presence of pollutants, such as: SO₂, CO₂, and resulting in higher rates of corrosion mainly in industrial environments, this is especially true on the coastal and marine areas. Most industrial units and plants in Brazil have areas classified in category CX Extreme Corrosivity or C5 Very High Corrosivity as per classification given in ISO 12944-9:2018.

Currently, the performance of the Securit 2® Elastomer has been proven very successfully in Brazil among leading companies across various industrial sectors, such as: mining, oil & gas refineries, petrochemical complex, steel mills, pulp and paper production, shipyards, marine oil platforms, port integrator pipeline terminals and other industrial plants.

Our industrial customers can count with our technical support and guidance for surface preparation and the system application methods.

With regular technical visits by Tinôco Anticorrosão technical team and their inspection and technical support thus ensuring the paint system is properly and evenly applied, with correct thickness for each of the coating layers. Thus, the performance of the system ‘in service’ can be guaranteed by Tinôco Anticorrosão for 7 years. Evidence has shown the Securit 2™ Elastomer system to being able to achieve longer periods in service without corrosion.

Tinôco Anticorrosão offers its customers at no additional cost, training, and technical instructions both theoretical and practical that assists its clients with the appropriate techniques and methods of application of the Securit™ 2 Elastomer. Working in partnership with customers, Tinôco Anticorrosão also monitors the integrity of equipment coated with the Securit™ 2 Elastomer evidencing extended in-service performance without corrosion.

The extraordinary performance of the Securit 2 ™ Elastomer system has been providing significant reduction in costs for our customers, both with assets maintenance and paint application. The corrosion protection afforded in the areas coated has increased the service life of the equipments. Therefore, the use of the Securit 2 ™ Elastomer system, has resulted in the reduction of the whole life cost of the equipment or asset.

Pioneer Technology Proven Track Record 7 Years of Manufacturers Corrosion Protection Warranty

WHERE ARE WE

INTERNATIONAL

CERTIFICATIONS

Proven in the marketplace, Tinôco Anticorrosão has the Securit™ 2 Elastomer approved at PETROBRAS* since 2003. It has also been tested and certificated by the FRAUNHOFERGESELLSCHAFT** international laboratory when exposed to cyclic performance tests in very high corrosivity conditions and showing good correspondence to the observations made under exposure to in-service conditions. The certifications and approvals obtained by Securit™ 2 Elastomer from these 2, well known and respected bodies validate the high-performance trajectory of the Securit™ 2 Elastomer observed in the field across several industry sectors.

The performance results obtained in laboratory tests under accelerated conditions and high corrosivity confirms the observed corrosion resistance of the Securit™ 2 Elastomer under: salt spray testing, humidity cabinet testing, stress corrosion and cyclic corrosion tests. The in-service performance of the Securit™ 2 Elastomer observed across various industrial sectors, applied to a variety of metallic e non-metallic surfaces and under highly corrosive atmospheres confirms the results obtained in the various laboratory tests.

Therefore, it provides assurance of the material corrosion protection efficiency and validate the securit ™ 2 elastomer performance warranty of 7 years.

Securit™ 2 Elastomer

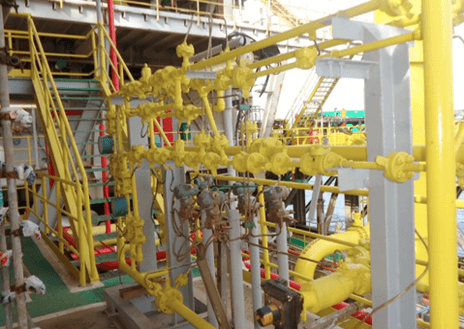

Client: MODEC OIL PLATFORMS

Year of Application: 2019

Applied to: Flanged Joint splints, supports

FPSO MV29

in the City of Caraguatatuba - São Paulo

Client: SUZANO (paper and cellulose)

Year of Application: 2022

Applied to: Steel Structure with Concrete

Supports, I-Beams Edges

Mucuri - Bahia

WHO ARE WE?

Founded in 1961, Tinôco Anticorrosão is a leading Brazilian company based in Rio de Janeiro and it is now managed by Marcelo Tinôco (the company CEO).

Since taking leadership of the company, Marcelo Tinôco implemented new practices related to product value creation and modernization of management practices that consolidated the importance of the Securit™ 2 Elastomer System. Over the years, the Securit 2™ eco-elastomer, single-component and cold-applied, has gained market recognition that identifies in the elastomeric technology a highly effective corrosion protective system for the industry.

The Securit ™ 2 Elastomer Coating System was developed and formulated to offer barrier corrosion protection in areas, equipment, metallic structures and interfaces between steel and concrete, in very high humidity areas. The Securit ™ 2 Elastomer has been formulated with state of-the-art polymers and combined with additives that ensure corrosion protection and waterproofing. This is specially indicated for the protection of areas and equipment under special conditions, such as:

Flanges, valves, gaps, junction plates, bolts, nuts, sharp corners, weld beading, corner sand edges, pipeline supports, support for structures, tank supports, clamps, and dissimilar material/metallic joints

Especially at these locations, where there are gaps, crevice corrosion can initiate as result of the formation of differential aeration cell or bimetallic corrosion. This type of corrosion is responsible for 50% the corrosion observed on site.

PIONEERING AND INNOVATION

Marcelo Tinôco

CEO Tinôco Anticorrosão

The elasticity of the Securit™2 Elastomer prevents the development of crevice corrosion by preventing the ingress of humidity and corrosive species into the gaps. This differs from other conventional systems which are not as flexible to accommodate the expansion and shrinkage of equipment/ materials during service/ exposure due to temperature changes and work conditions.

The efficiency of the Securit ™ 2 Elastomer has been proven in the field mainly in industrial plants, offshore and onshore units, environments that present high rates of corrosiveness due to marine (salt spray) atmosphere and polluted (SO₂, CO₂) atmospheres, high concentration of polluting gases and chemical agents are often found in these industrial sites.

Camaçari Industrial Complex - Bahia

The manufacture of the Securit ™ 2 Elastomer is carried out in a joint venture between Tinôco Anticorrosão and Química Industrial União Ltda – a traditional Brazilian paint industry founded in the 1960s – However, this joint venture production of Securit ™ 2 Elastomer has been aligned to the commitment to quality and technological innovation and ecologically and environmental practices which are part of the DNA of Tinôco Anticorrosão

Based on its successful track record and without losing focus on its important role in the health & safety, protection, sustainability, productivity, and cost reduction of the industrial sector, Tinôco Anticorrosão’s current investment policy is also focused on the expansion of its product line

WHERE DO WE OPERATE

In Brazil, Tinôco Anticorrosão operates with renowned industrial complexes, petrochemical complexes, production, and logistics companies on both: offshore and onshore activities, mainly located in the Brazilian marine coast and situated in areas of high corrosion rates.

The Securit™ 2 Elastomer is a water-based single component, elastomeric asphalt composition coating system. Formulated with state-of-the-art polymers combining additives that ensure excellent corrosion protection performance and optimum adhesion to different surfaces, such as: carbon steel, stainless steel, aluminum, hot dip galvanized, concrete etc.

CORROSION

It is a natural process and a crucial problem around the world due to its economic and environmental consequences with an impact on productivity and on the health, and safety of the workforce.

Atmospheric corrosion can lead to severe degradation of metallic and non-metallic structures, causing high financial damage, serious accidents, and environmental disasters. The losses associated with corrosion in Brazil are estimated to be around US$10 billion, mostly in the oil & gas industry.

The overall cost of corrosion is estimated at US$2.5Trillions, which equates to 3.4% of World GDP (Source: AMPP, The Association for Materials Protection and Performance). However, companies could save between 15 and 30% of this cost by using appropriate corrosion control practices. With billions of dollars savings that would be available for investments in other areas.

The durability of the infrastructure assets of the industries is reduced by the action of corrosion that is accelerated by: the presence of pollutants in the atmosphere, high relative humidity, marine atmosphere (Sodium chloride salts) and high temperature.

Annual Average Temperature

WHERE ARE WE

The properties and features of application of the Securit™ 2 (environmentally friendly, non – flammable, non- toxic) Elastomer, allows for a wide use in various industrial environments and have many advantages over other corrosion protection application methods. The system high elasticity ensures simple action for removal of the system from screws and flanges surfaces during maintenance or repair. In addition to its elasticity, its excellent adhesion to both metal and concrete surfaces allows the coating to encapsulate screws (heads and threads) and prevents breaks and / or cracks in the protective film thus preventing ingress of moisture and oxygen, which causes the onset of corrosion. Cold application by means of a brush is simple and fast (check out our Technical Bulletins for Primer and Finishing/top coat).

The system is compatible with metallic structures of various shapes and sizes, equipment of complex geometries preventing initiation and propagation of crevice corrosion, galvanic corrosion, and atmospheric corrosion. The Securit™ 2 Elastomer protects and provides sealing with superior performance when compared to less flexible coating systems and other more conventional anticorrosive treatments. Its flexibility places it in an outstanding position in the industrial corrosion protection market.

Nowdays, the Securit™ 2 Elastomer system is a regular requirement as part of the technical specifications of several companies and also required in several industrial maintenance projects mainly on offshore production platforms PETROBRAS, MODEC, as well as at Braskem’s petrochemical plants, at ArcelorMittal, (steel production), Gas & Energy Transpetro/TAG/ENGIE ( PETROBRAS) pipeline terminals, SUZANO e BRACELL (pulp and paper industries), VALE (mining units), ENEVA (thermoelectric plant) in Pecém thermoelectric complex, CEARÁ, at BASF Acrylic Complex at Camaçari Industrial Complex in BAHIA, among other companies.

The Securit™ 2 Elastomer is the only product with in service applications showing more than 7 (seven) years of good corrosion protection performance in flanged joints.

Suape-Pernambuco Port Industrial Complex

Photo: Rafael Medeiros

Tinôco Anticorrosão manufacturing is located in Rio de Janeiro and the Securit™ 2 Elastomer system is distributed from Rio de Janeiro to all Brazilian territory.

The present service structure has the potential for global distribution. In Brazil, we reach all regions and have the support of local representatives in many of the Brazilian states, such as: CEARÁ, PERNAMBUCO, ALAGOAS, BAHIA, ESPÍRITO SANTO and RIO DE JANEIRO. Our technical team is highly trained and experienced providing support and guidance on the technical application procedures and characteristics of the Securit™ 2 Elastomer system.

WHAT DO WE DO

REFERENCE IN CORROSIVE PROTECTION

The SECURIT™ 2 ELASTOMER System with emulsion in water and cold applied provides excellent barrier protection and has been successfully used under special industrial conditions. The different industrial sectors witness to the advantages of the SECURIT™ 2 ELASTOMER when compared to other corrosion protective coatings. It has physical properties that guarantee its high performance and optimum adhesion on substrates such as: carbon steel, hot dip galvanized steel, stainless steel, and aluminum in addition to good resistance to polluting gases, marine atmosphere.

SECURIT™ 2 ELASTOMER

Client: ACELEN (PETROBRAS/RLAM)

Year of Application: 2014

Applied to: Flanged joints, Valves

Landulpho Alves-Mataripe Refinery, Bahia

ISO 12944-9:2018: Extreme CX

Corrosiveness Exposure Period: From 2014 to 2020

VALE

JUNCTION PLATES

VITÓRIA /ESPÍRITO SANTO STATE

ISO 12944-9:2018: Corrosivity C5 Very High

QUALITY INNOVATION AND CUSTOMER CARE

Through regular technical visits by Tinôco Anticorrosão quality team offer training to industrial customers. These get all instructions and technical support for the correct application the Securit™ 2 Elastomer system thus preventing the onset of premature defects.

The use of the Securit™ 2 Elastomer system it is possible to prevent the formation of differential aeration cells and Oxygen concentration differential which are likely to be formed in the gaps, thus having a preventive crevice corrosion action on corners and gaps corrosion. This is because the system has sufficient flexibility to seal the gaps. The maintenance sector has observed that the Securit™ 2 system has the correct balance of fundamental characteristics and physical properties such as: flexibility, elasticity, and adhesion) to promote the corrosion protection by barrier.

In response to major industry demands for sustainability, efficiency, and safety, Tinôco Anticorrosão has gathered photographic evidence, client’s statements, and inspection reports as evidence to the Elastomer Securit®2 system quality and integrity over the years. This also demonstrates the system is capable to retain its integrity in spite of the expansion and shrinkage movement caused by temperature changes and/or mechanical action of the metallic structures/ equipment.

Aligned to the organisational objectives a Tinôco Anticorrosao, support its industrial clients in their search for operational excellence in a sustainable way and over a long term.

VALE

Steel Bases/Concrete Conveyor Belt

VITÓRIA /ESPÍRITO SANTO

ISO 12944-9:2018: Corrosivity C5 Very High

VALE is one of the largest mining companies in the world, with a leading position in the iron ore and nickel segments. In addition to mining, it operates in logistics with railways, ports terminals and state-of-the-art infrastructure, in energy and steel production.

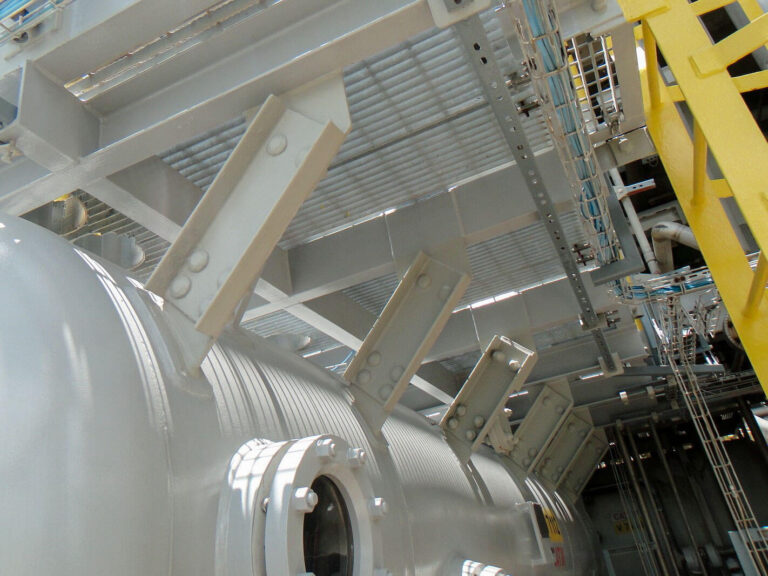

BASF

From 2015 to 2019

4 years of proven corrosion protection

ISO 12944-9:2018: Corrosivity C5 Very High

BASF is a german global chemical company and world leader in paint and chemicals production. BASF’s acrylic compounds complex at the Camaçari Industrial Complex in the State of BAHIA produces acrylic acid, butyl acrylate and superabsorbent polymers (SAP), with a production capacity of 160,000 tons of acrylic acid per year.

ARCELORMITTAL Tubarão – ES

Period 2008 to 2020

13 years of proven protection

ISO 12944-9:2018: Corrosivity C4 high

ARCELORMITTAL Group is a a world leader in steel production and one of the largest in mining.

SUCCESSFUL

PARTNERSHIPS

Sector: Mining

Location: Vitória/ES; Itaguaí/ RJ

ISO Rating 12944-9:2018: High Corrosivity C4

Sector: Oil & Gas Location: Campos Basin/RJ; Espírito Santo Basin/ES; Santos Basin/SP

ISO 12944-9:2018 – Corrosivity: Extreme CX, C5 Very High, C4 High

Sector: Pulp and Paper

Location: Mucuri – BA

ISO12944-9:2018- Corrosivity: Extreme CX, C5 Very High, C4 High

WHY USE THE

SECURIT™2 ELASTOMER?

Industrial coating remains the most cost-effective

treatment for corrosion protection in industry.

The use of industrial coating has a competitive cost compared to other linings. Despite these well-known benefits conventional paint system may fail for many reasons such as: due to inadequate treatment for specific areas, such as:

crevices, flanges and screws/ nuts, pipe support, areas of high humidity, support structures. At interface sites such as: between soil atmosphere and water atmosphere, among others.

The biggest differential of the Securit™ 2 Elastomer when compared to other coating systems, is its flexibility that adapts and wraps itself to these special sites. It also has advantages especially because it is a water-based product and of simple removal from flanges and screws surfaces when any intervention is necessary.

SECURIT ™ 2 ELASTOMER

ISO 12944-9: 2018: Extreme CX Corrosivity

BRASKEM - Chloro Soda 1 - Alagoas

Application of Elastomer in flanges, Complex Structures

ISO 12944-9:2018: Corrosivity C5 Very High

Client: braskem q1 – Petrochemical Camaçari Industrial Complex – Bahia

SECURIT ™ 2 ELASTOMER it is especially suitable for corrosion protection on surfaces with critical areas and geometric profiles.

And mainly, because it is a viscous paste and extremely flexible product, its application is carried out by spreading it over the surface, different from traditional painting systems.

The Securit™ 2 Elastomer ensures corrosion protection of critical areas, especially because it is complemented using gap beading (low density polyethylene foam) forming a high-performance system in the protection of gaps or similar areas. This combination is especially used where there are crevices between flange faces and between dissimilar materials as metal/concrete interfaces specifically at the gaps of tank bottoms and supports.

LOCATION: BARRA DO RIACHO/ESPÍRITO SANTO - GAS PIPELINE

Client: ENGIE (TRANSPETRO - TAG)

Applications of the Securit™ 2 Elastomer | After 8 Years and 6 Months | Excellent Corrosion Protection and High UV Resistance

Period: From 2012 to 2021

Application of the Securit™ 2 Elastomer in CRITICAL AREAS OF THE SITE which were exposed to both: atmospheric and galvanic corrosion: BRACKETS, FLANGES, CASES, NUTS AND VALVES

In a Gas Distribution Terminal, safety is paramount and cannot be compromised. Corrosion protection technology and equipment integrity maintenance play a crucial role in preventing accidents and unscheduled downtime. ENGIE/ TRANSPETRO/TAG believes in the continuous technical partnership with Tinôco Anticorrosão to ensure and extend the life of its assets and each component in the systems, without liquid or gas leakages.

Photographic records of the Securit™ 2 Elastomer coating system showing excellent corrosion protection and UV resistance after 8 years and 6 months of application in the ENGIE/ TRANSPETRO/ TAG Unit (ERPARCEL)/ES, gas delivery point for SUZANO ARACRUZ (pulp production) and near the Barra do Riacho Waterway Terminal – TABR (marine atmosphere). The life of the corrosion protection of Flanges, Valves, Bolts, Nuts, Crevices, Weld beading and Clamps located in a highly aggressive corrosive environment as result from the combination of industrial (cellulose) and marine atmospheres, in addition to the presence of chemicals such as: caustic soda, sodium chloride, chlorine dioxide, hydrochloric acid and its proximity to the sea, the corrosion rate has been quadrupled. Additionally, it suffers the direct action of marine winds with a high sodium chloride concentration.

Technical visit in June/2021 to the Valves area – Gas pipeline Lagoa Parda Vitória - with cut-out in the elastomer coating for inspection of coating performance and to check for the onset of corrosion - No corrosion was observed.

RESULT: 8 YEARS AND 6 MONTHS WITHOUT CORROSION

ISO 12944-9:2018: Extreme CX Corrosivity

TESTIMONIALS OF

CLIENTS

Alan Colavolpe

"It's been five years without any type of corrosion, which is a breakthrough in corrosion protection coatings. The application of the Securit ®2 Elastomer system took place in June 2015 in a CX - Extreme Corrosivity class of aggressiveness - at the BRASKEM plant at the Camaçari Petrochemical Complex site in the state of Bahia(...) The technology used before the Securit ®2 Elastomer was quite ineffective, and we sought in the market an alternative that would bring value to this highly corrosive area and the Securit ®2 Elastomer proved very efficient, mainly due to its similarity of application with conventional liquid paints (...) Although the flange had previously suffered mechanical damage the Securit ®2 Elastomer still fulfilled its protection to maintain protection, in this case providing an effective a protective barrier (...) As a customer, I am happy with the outcome and I trust that in addition to the initial 5 years warranty provided by the manufacturer for this technology, we may achieve a total life expectancy of ten (10) years. Using a product that offers this high level of effectiveness shows that we are moving in the right direction. "

Adilson Gonçalves Figueira

"Under my supervision, the company RIP / KAEFER performed the maintenance and painting services of the ARCEL ERP unit. We found all flange joints coated with Securit™ 2 Elastomer in good sealing condition and without onset of corrosion. There was no need for maintenance/ repair. We only applied a top layer of yellow liquid polyurethane-based paint to reinstate the surface gloss and aesthetics of the elastomeric coating system after 7 years exposure following from its original application"

TECHNICAL TESTS AND APPROVALS

SECURIT™ 2 ELASTOMER

Manufacturer’s 7 – year corrosion protection warranty

PETROBRAS / CENPES

LEOPOLDO A. MIGUEZ DE MELLO – PETROBRAS RESEARCH AND DEVELOPMENT CENTRE: Test report TMEC Nr 088/03 Corrosion resistance under salt spray atmosphere (ASTM B117) and water resistance at 100% relative humidity (ASTM D-2247 – Humidity cabinet exposure): NO CORROSION WAS OBSERVED AFTER 3000 HOURS OF EXPOSURE

THE FRAUNHOFER-GESELLSCHAFT GERMANY

FRAUNHOFER Nr Test Report.: P-FhAGP-1712-010

It is stated IN ISO 12944-9: 2018: No corrosion after a period of 25 weeks exposure (25 cycles) comprising of:3 days of condensation / exposure to UV according to DIN EN ISO 1674-3: 2013: exposure to 3 days for salt spray atmosphere according to DIN EN ISO 9227: 2017- and 1-day exposure at low temperatures at -20°C

Corrosion protection properties are based on the barrier protection mechanism and are achieved even when applied on surfaces with mechanical or manual treatment, as per ISO 8501- 1 Standards St 3 and St 2.

SECURIT™ 2 ELASTOMER

Corrosion Protection System consists of:

2 x coats of 200 μm (each) of Securit™ 2 PRIMER Elastomer (water-based asphaltic composition with the presence of rubber) +

2 x coats of 100 μm (each) of Securit Elastomer™ 2 FINISH (all colors)

Key Benefits

- Proven extension of asset life

- Significant reduction in maintenance costs

- Environmentally friendly, water-based

- Simple and quick to apply with brush

- Fast curing reducing system application/ overcoating time and resistant to direct naked flame impingement

- All colors as per: MUNSELL, RAL, PANTONE and PETROBRAS colour standards

- Easy application and coverage of screws and flanges for new or maintenance applications

- Excellent adhesion to metal and concrete, high elasticity,

- Accommodates thermal expansion, contractions, and/or vibrations movements without development of cracks or delamination

- Maximum service temperature resistance for metallic surfaces of 100oC and maximum service relative humidity of 95%

- Does not require skilled labor and the use of special equipment or machinery for its application

- Prevents crevice, galvanic and atmospheric corrosion,

- Protects and seals gaps on any complex equipment and geometries

- Maximum storage period: 24 months from manufacture date

- Rua da Assembleia, 85 Gr.1903 - Rio de Janeiro - RJ - Brasil CEP : 20011-001

- mtinoco@tinocoanticorrosao.com.br

- +55 21 3553-1953

- +55 21 3553-1954